LFAM 3D Printing

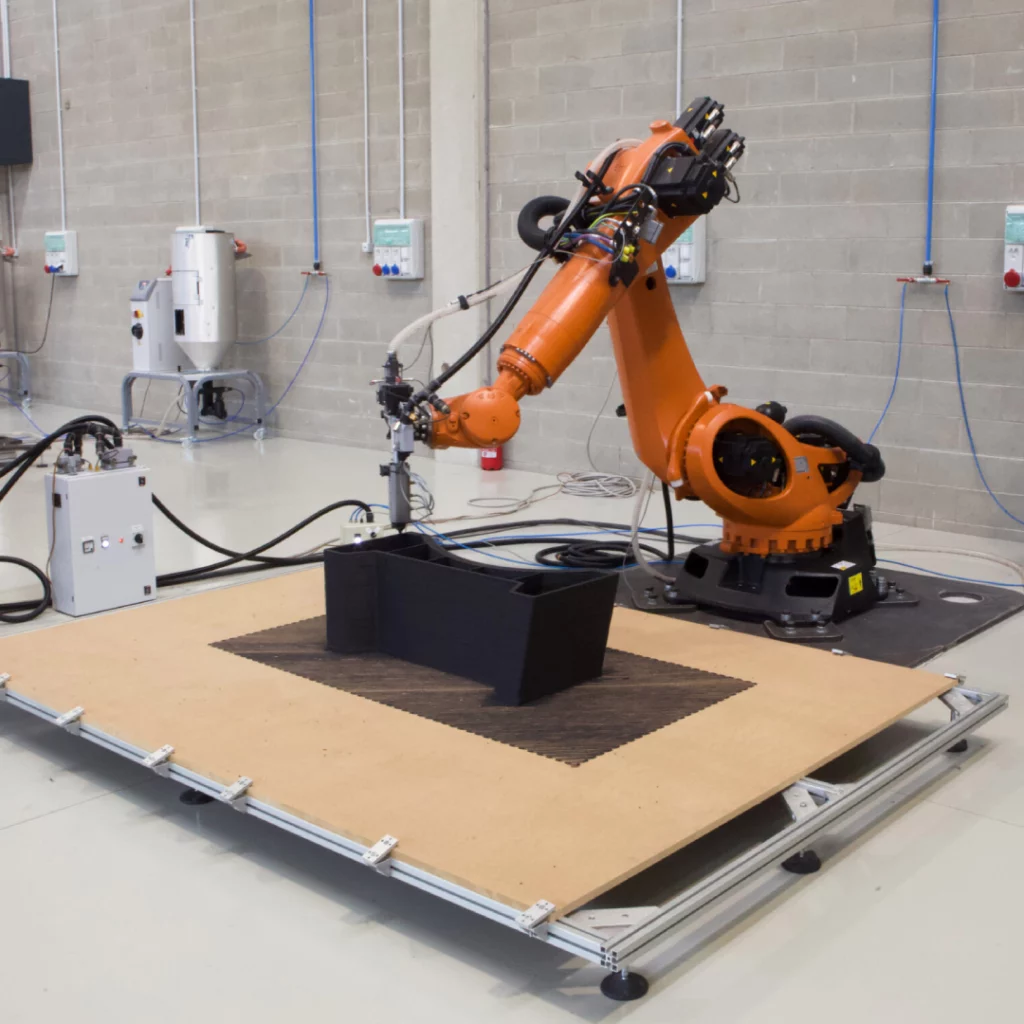

Large Format Additive Manufacturing (LFAM) enables the 3D printing of large objects using a wide variety of fully customized materials.

Which advantages does LFAM offer?

Large Format

The HERON robotic arm 3D printing using LFAM allows for the 3D printing of monolithic parts up to 3x3x3 meters in volume.

Custom Materials

Thanks to the use of pellet-form material, the HERON arm allows for the utilization of customized materials and blends of thermoplastics and custom colors.

Unique Designs

Thanks to its production method, LFAM 3D printing allows for the creation of unique designs and colorations, perfect for sectors such as design, furniture, and decorative accessories.

Available materials for LFAM

LFAM printing uses plastic materials in pellet form. It is possible to create custom pellet blends based on the characteristics required by the project.

Contact our team to find out which solutions may be best suited for you!

Richiedi una quotazione custom

How does LFAM 3D Printing work?

Very similar to FDM technology, the material in pellet form (granules) is melted and extruded through the print nozzle. The print head is mounted on a robotic arm that moves across the print bed, constructing the object by depositing layer after layer.

Parts printed with this technology can be assembled together to achieve dimensions beyond the limits of standard production.

Furthermore, the produced artifacts can be considered ready right after production, as they do not require specific post-print treatments.