SLA 3D Printing

Stereolithography, commonly known as SLA, allows for the rapid production of models with a high degree of precision and extremely high surface quality.

SLA technology combines precision, exceptional aesthetic quality, and a wide selection of materials.

Which advantages does resin offer?

Superior Surface Quality

La stampa 3D SLA è tra quelle tecnologie che riescono a garantire una qualità superficiale migliore.

Le superfici sono lisce e compatte, ideali per prototipi estetici ready to use.

High Detail Definition

Thanks to high-precision lasers, SLA technology allows for maintaining an exceptionally high level of detail, even on very small features.

Special Materials

With SLA technology, it is possible to use materials with very specific characteristics, such as transparent, castable, and rubber-like materials.

Available materials for LFAM

DWS INVICTA

DWS THERMA

DWS VITRA

DWS FUSIA

DWS FLEXA

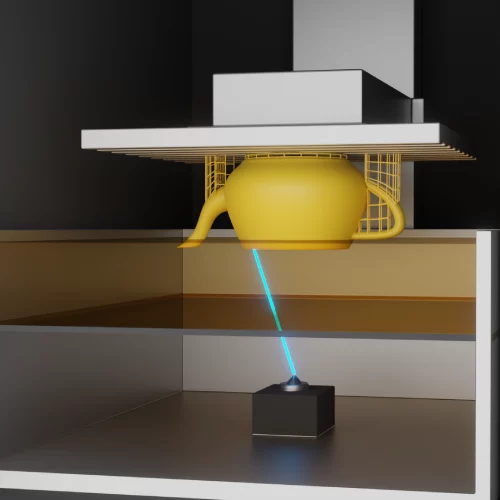

How does SLA 3D printing work?

The print plate descends into the vat containing the resin. At the bottom of the transparent vat, a laserhits the resin, tracing the profile of the object and solidifying the material through a process called “polymerization."

The printing platform rises, and then the printing step is repeated.

Parts printed with this technology require supports during printing, which are easily removed at the end of the process.

At the end of the printing process, the parts are subjected to an isopropyl alcohol bath to remove any excess resin, and are then “cured” in a specialized UV oven to complete the solidification process.